Ntag 213 Hard PPS RFID Laundry Tags for Clothes

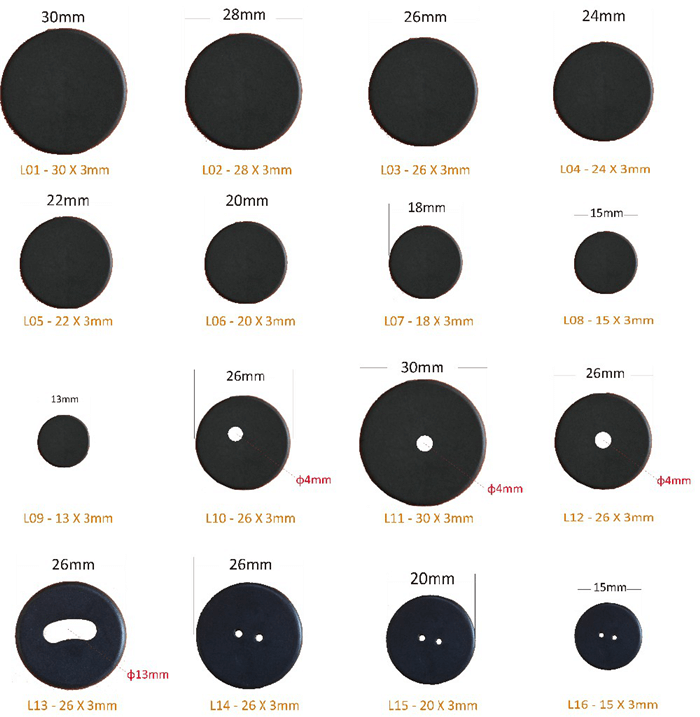

Shape & Dimension

1. Tag Size:Diameter 15mm,18mm,20mm,22mm,23mm,24mm,30mm or customized.

More Styles

|

Product Name |

Washable PPS Laundry RFID Tag for Cloth Washing |

|

Color |

White,blue ,black,yellow or any pantone color |

|

Material |

Silicone/plastic |

|

Size |

20mm/26mm/customized |

|

Chip |

U Code 7,Alien Higgs3, 4 etc |

|

Memory Size |

512 User Bits |

|

Operating Mode |

R/W |

|

Typ. required activation |

112 dBμA/m |

|

Typ. required activation |

115 dBμA/m |

|

Protection Class |

IP 68 (condition: water pressure 45bar, 10h) |

|

Reading range |

3M (Related to reader performance and working environment) |

|

Standards/Protocols |

EPC CLASS1 GEN2, ISO 18000-6C |

|

Printing |

LOGO & Silk Screen Printing |

|

Main Features |

Adjustable,Soft,Flexible,Convenience Wearing, Waterproof, Quakeproof, etc. |

|

Application |

Amusement park,Clubs,Beach baths,Spa Center etc |

|

Min.Order Quantity |

300 Piece/Pieces |

|

Life Time |

100,000 cycle times |

|

Frequency |

Chip Model |

Read/Write |

Memory |

|

Low Frequency |

EM4100/ EM4102 |

R/O |

64bit |

|

EM4200 |

R/O |

64bit |

|

|

EM4305 |

R/W |

512 bit |

|

|

T5577 |

R/W |

363 bit |

|

|

Hitag 1 |

R/W |

2K bit |

|

|

Hitag 2 |

R/W |

256 bit |

|

|

High Frequency |

MF 1K(S50) |

R/W |

1Kbyte |

|

MF 4K(S70) |

R/W |

4K byte |

|

|

Ult |

R/W |

512 bit |

|

|

Ult C |

R/W |

1536 bit |

|

|

N203 |

R/W |

168 byte |

|

|

N215/216 |

R/W |

504/888 byte |

|

|

N213 |

R/W |

144 byte |

|

|

D21 |

R/W |

2K byte |

|

|

D41 |

R/W |

4K byte |

|

|

D81 |

R/W |

8K byte |

|

|

I CODE SLI |

R/W |

896 bit |

|

|

I CODE SLI-X |

R/W |

1024 bit |

|

|

I CODE SLIX-S |

R/W |

2048 bit |

|

|

UHF 860~960MHz |

Alien H3 |

R/W |

64 bit |

|

Alien 9662 |

R/W |

512 bit |

|

|

Monza 4 |

R/W |

512 bit |

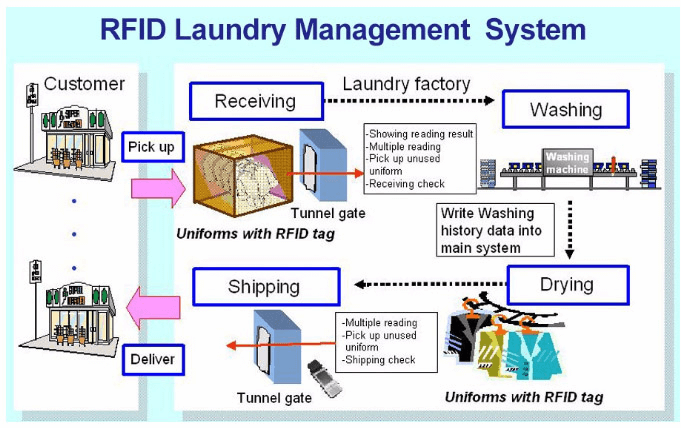

Application

Towel and bed sheet Laundry management Uniform Laundry Management

Solution description

The whole system include 5 steps as below:

• Laundry factory pick up uniforms from customer, and sew RFID laundry tag on the uniforms.

• All the uniforms pass the runner gate, the reader on the gate both side can scan multiple tags at the same time, system can know the specific uniforms quantity enter at the same time.

• During the washing line, also have RFID reader on the line.it can write washing history data into tags, the main system will keep record.

• After wash,need come to drying line, it can use RFID reader to check inventory.

• After finish wash and dry, it will pass the runner gate again,when reader scan, main system can know how many uniforms finish laundry and left at what time.